10 Sep When Multi-Shot Molding Makes Sense for Your Product Design

When creating quality plastic products, the process is crucial, especially in a field with stringent precision requirements. Multi-shot molding is a reliable method for creating durable products while streamlining the manufacturing process. But how can you know if multi-shot molding makes sense for your product design? Today, Hudson Valley Plastics is outlining five signs that it could be the right choice.

Ready to Try Multi-Shot Molding for Your Next Project? Contact Hudson Valley Plastics today and let our expert team discuss your options.

What is Multi-Shot Molding?

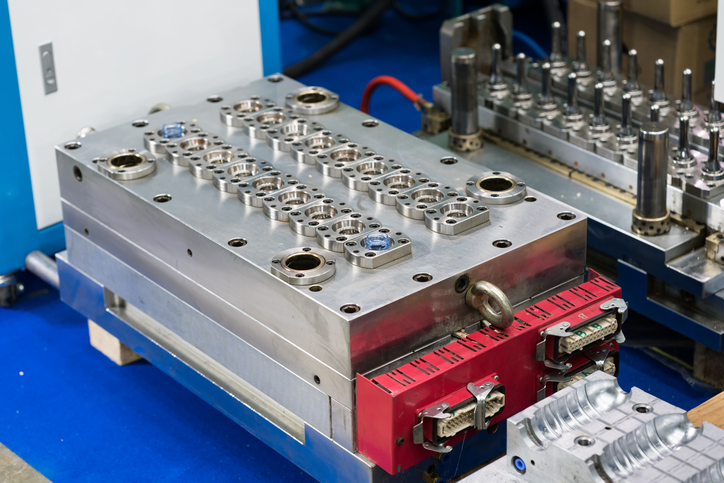

Multi-shot molding, also known as two-shot injection molding, is a manufacturing process where two different materials or colors are injected sequentially into the same mold during a single production cycle. Unlike traditional molding that requires separate operations and assembly steps, multi-shot molding creates complex, multi-material components in one continuous process.

The process works by injecting the first material into the mold, then rotating or repositioning the part before injecting the second material. This creates either a chemical or mechanical bond between the materials, depending on their compatibility. Common applications include tool handles with soft grips, electronic housings with transparent windows, and medical devices combining rigid and flexible components.

Working with experienced manufacturers is crucial for material compatibility, as not all plastic combinations bond effectively. Professional material compatibility guidance ensures successful chemical bonding and prevents delamination issues that can compromise product integrity.

5 Signs That Multi-Shot Molding is the Right Choice

Durability is a High Priority

Mechanical joining methods like screws, adhesives, or snap-fits simply cannot match the strength of molecular-level bonding. Multi-shot molding creates bonds at the molecular level between compatible materials, dramatically increasing overall product durability compared to assembled components.

This molecular fusion eliminates the weak points typically found in mechanically fastened assemblies. Instead of relying on external fasteners that can loosen over time or adhesives that may degrade, multi-shot molding creates a permanent bond that often exceeds the strength of the individual materials themselves.

Streamlining is Paramount

Multi-shot molding significantly reduces production time by eliminating multiple steps in the production process. Rather than molding separate components and transferring them between assembly stations, you can create multi-material products in a single cycle, reducing handling, labor costs, and potential quality issues.

This streamlined approach eliminates the coordination challenges of managing separate molding operations, inventory of individual components, and complex assembly procedures. The result is faster time-to-market and reduced manufacturing complexity for products requiring multiple materials or colors.

Precision is Critically Important

Tolerances for multi-shot molding can achieve extremely exacting specifications because both materials are molded within the same tool during the same cycle. This eliminates the cumulative tolerance buildup that occurs when assembling separately molded components, creating exact fits between different material sections.

This precision proves especially valuable for products requiring tight seals, precise alignments, or exact color registration. Medical devices, electronic housings, and precision instruments all benefit from the dimensional accuracy achievable through multi-shot molding versus traditional assembly methods.

Aesthetics Need to Be Considered

Multi-shot molding enables you to add colors, textures, and design elements without the need for secondary painting or printing operations. This approach creates more durable aesthetic features that won’t fade, chip, or wash off over time, unlike applied coatings or labels.

The process allows for sharp color transitions, complex graphics, and textural variations that would be impossible or costly to achieve through post-molding decoration. Automotive trim pieces, consumer electronics, and appliance components frequently utilize multi-shot molding for superior aesthetic durability.

Because the aesthetic elements are integral to the molded part rather than applied afterward, they maintain their appearance throughout the product’s service life, supporting brand quality and consumer satisfaction over time.

Waste Reduction is Needed

Since multi-shot molding creates complete components in one step, it greatly reduces the need for modifications, trimming, material waste from separate operations, and production re-runs due to assembly defects. The elimination of secondary assembly operations also reduces packaging waste and handling damage.

Material utilization improves because runner systems can be optimized for both materials simultaneously, and there’s no waste from adhesives, mechanical fasteners, or rejected assemblies. This efficiency becomes increasingly important as sustainability concerns drive manufacturing decisions.

At Hudson Valley Plastics, our no minimum order quantity approach enables efficient multi-shot production even for moderate volumes, allowing you to minimize inventory waste while accessing advanced manufacturing capabilities typically reserved for high-volume applications.

Hudson Valley Plastics Can Help With Your Multi-Shot Molding Project

So, is multi-shot molding right for your project? If you have moderate to high production volumes and want to reduce waste and steps in the production process while improving durability and precision, it could be the ideal solution. The next step is contacting an expert multi-shot molding manufacturer to explain your needs — a manufacturer like Hudson Valley Plastics.

At Hudson Valley Plastics, we’re interested in building long-term relationships with our clients. That’s why our professional, experienced team makes customer satisfaction a high priority. When you partner with us, you can expect comprehensive support from initial design consultation through full-scale production, backed by decades of advanced molding expertise.

We leverage 80+ years of manufacturing experience to understand material compatibility and bonding requirements. Our multi-shot capabilities, integrated with our 28 injection molding presses, ensure optimal material selection and processing parameters for maximum durability in demanding applications.

Ready to reap the benefits of multi-shot molding? Contact Hudson Valley Plastics to discuss your options and start improving your products’ durability, aesthetics, precision, and overall manufacturing efficiency.

No Comments