10 Sep When to Choose Hot Plate Welding for Your Pharmaceutical Assembly

Unlike other forms of manufacturing, hot plate welding offers some unique advantages during the production process. Whether you need a reliable way to connect multiple plastics or require packaging with a strong seal, hot plate welding provides a great opportunity to create pharmaceutical products and packaging with precision and accuracy.

But how do you know when you should choose hot plate welding for your project? Here are six times when this method can greatly improve your manufacturing process.

Ready to Partner with the Experts in Hot Plate Welding? Contact Hudson Valley Plastics today to learn how our experienced team can help with your next project.

What is Hot Plate Welding?

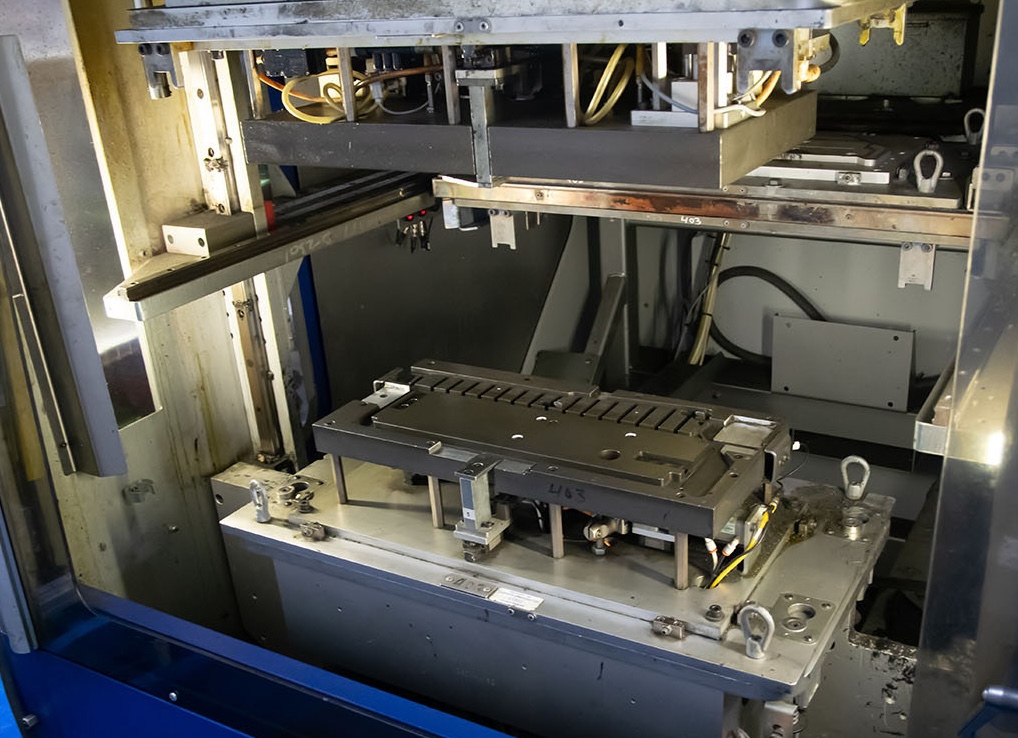

Hot plate welding is a thermal joining process where two plastic parts are heated by contact with a heated platen, then pressed together to form a strong, permanent bond. Unlike ultrasonic welding, which uses vibration, or adhesive bonding that relies on chemical agents, hot plate welding creates molecular fusion between compatible thermoplastic materials through controlled heat and pressure.

This process offers precise temperature and pressure control, making it ideal for pharmaceutical applications where consistency and reliability are essential. The method works particularly well with materials like polypropylene, polyethylene, and other thermoplastics commonly used in medical packaging and device assembly.

6 Times When Hot Plate Welding Makes Sense

When You Need a Strong Seal

Depending on your product, you may need packaging that has tight seals. This is especially true for powders or liquids that require protection from moisture, contamination, or tampering. Traditional sealing methods may not provide the hermetic seal strength required for pharmaceutical applications.

Hot plate welding is ideal for creating these seals needed for airtight or leak-proof containers. The molecular fusion achieved through hot plate welding creates seals that often exceed the strength of the base material itself, providing superior protection for sensitive pharmaceutical products.

When You Need to Use Multiple Plastic Types

Bonding two different types of plastic together can be difficult with traditional joining methods, but hot plate welding allows you to do so easily when materials are compatible. This compatibility extends to various thermoplastic combinations commonly used in pharmaceutical applications.

This flexibility allows you to have more design freedom with your packaging and device assemblies. For example, you might need to join a clear viewing window to an opaque container body, or combine different material properties in a single assembly for optimal performance.

When Looks Matter

Even small defects in pharmaceutical packaging can greatly impact consumer trust and brand perception. Visual quality becomes especially critical for over-the-counter medications and consumer health products where package appearance directly influences purchasing decisions.

Hot plate welding allows you to get a clean, professional finish every time. The controlled heating and pressure create consistent weld lines without the flash or aesthetic issues that can occur with other joining methods. This consistent appearance supports pharmaceutical branding requirements and FDA tamper-resistant packaging standards that require clear visual indicators.

When You Have High Product Volumes

Hot plate welding is repeatable and scalable, with high production speeds that make it perfect for projects with high production volumes. The automated nature of the process ensures consistency across thousands or millions of assemblies.

This scalability proves especially valuable for pharmaceutical contract manufacturers who need reliable joining processes that can accommodate varying production demands without sacrificing quality. The repeatability of hot plate welding supports the validation requirements essential for pharmaceutical manufacturing.

Hudson Valley Plastics integrates hot plate welding with our comprehensive assembly capabilities, offering production volumes from 10,000 to 1M+ pieces with no minimum order quantities — ideal for both pilot production and full-scale pharmaceutical manufacturing.

When You Can’t Use Adhesives

Some pharmaceutical products cannot be packaged using any type of chemical adhesive. This restriction exists because potential interactions between medications and adhesives, leaching risks, or Current Good Manufacturing Practice (CGMP) compliance issues can create serious problems for pharmaceutical applications.

Hot plate welding provides a safe alternative that eliminates chemical adhesive concerns entirely. The thermal fusion process creates bonds without introducing foreign materials that could interact with pharmaceutical formulations or create regulatory compliance issues.

When Regulatory Compliance is a Factor

Hot plate welding is perfect for projects that need to meet tight standards and tolerances to stay in compliance with regulations. The process provides consistent, validated joining that supports the documentation requirements essential for pharmaceutical manufacturing.

The controlled temperature and pressure parameters of hot plate welding create traceable, repeatable results that support validation protocols required for pharmaceutical applications.

Ready to Partner with a Hot Plate Welding Expert?

Hot plate welding is a great way to keep your pharmaceutical products consistent, precise, and in compliance with relevant regulatory requirements. But how can you be sure that you will select the right manufacturing partner when the time comes?

Hudson Valley Plastics has you covered. We have 80+ years of experience in plastic manufacturing and use hot plate welding to create pharmaceutical packaging and products with tight tolerances. When you partner with us, you can rest assured that your products are in capable professional hands.

Our integrated approach combines hot plate welding with ultrasonic welding, mechanical fastening, and other assembly capabilities, providing comprehensive solutions for complex pharmaceutical assembly requirements under one roof.

Ready to streamline your pharmaceutical assembly process? Contact Hudson Valley Plastics to learn how hot plate welding can benefit projects that require design and manufacturing precision.

No Comments