03 Nov Vision Inspection Systems: Automated Quality Control for Medical Manufacturing

Medical manufacturing doesn’t leave any room for error. Every component must meet strict standards to ensure patient safety and regulatory compliance. That’s why more manufacturers are turning to vision inspection systems. This equipment removes the limitations of manual inspections, which reduces risk for your company.

Partnering with a manufacturer that utilizes vision inspection systems can yield significant benefits for your business. Below, we’re exploring what these systems do and how Hudson Valley Plastics can improve your operations. Let’s dive in.

Looking for a medical manufacturer that can provide tight-tolerance, reliable components? Contact Hudson Valley Plastics to partner with our team.

What Are Vision Inspection Systems?

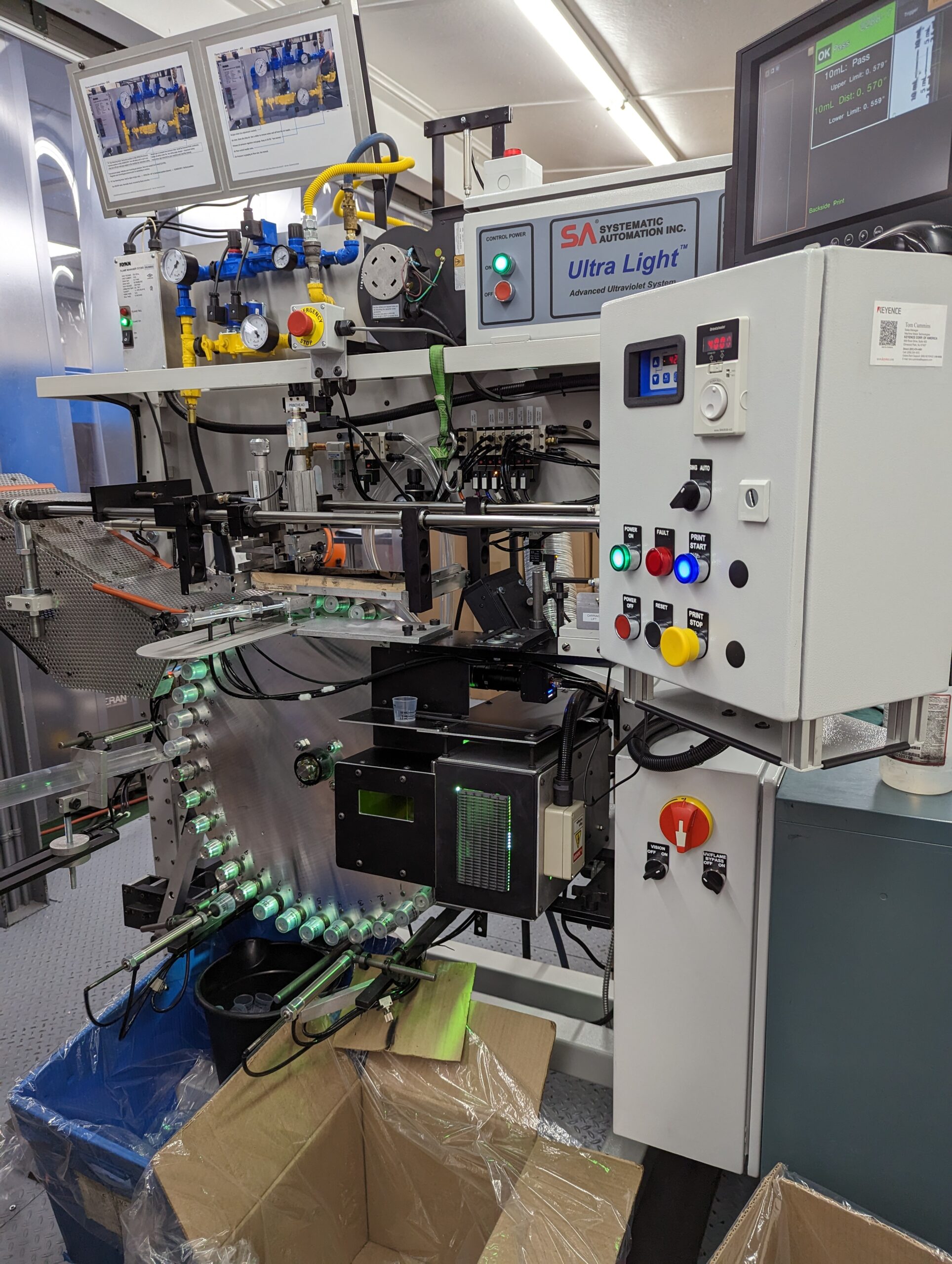

Vision inspection systems are automated equipment that use cameras, sensors, and software to detect flaws, verify dimensions, and ensure quality. They capture high-resolution images of every component and analyze them with advanced software. The program compares each part against a digital standard in real time. It quickly flags small deviations, which can improve outcomes for businesses. This machinery can:

- Check molded parts for cracks, voids, or warping

- Verify dimensions, ensuring parts meet strict tolerance requirements

- Identify cosmetic flaws

- Confirm multi-part components are correctly joined

- And more

For medical components, vision inspection systems will commonly be used to verify certain types of components. This might be ensuring syringe barrels are free of cracks, verifying that vial stoppers are properly sealed, or confirming that catheter tubing maintains a consistent wall thickness. It might also be used to verify labeling and seals on packaging.

Why Automated Vision Inspection Matters in Medical Manufacturing

Vision inspection systems are more reliable than manual inspection. Manual processes are slower, less scalable, and more prone to human error. With automated solutions, you can expect the following benefits:

Regulatory Compliance

To meet FDA and ISO standards, your parts need to be as precise as possible. Automated vision inspection helps you meet stringent regulatory requirements. They eliminate variation between human inspectors. Meaning, every single component is measured against the same standard. Detailed data also supports easier audits and creates a digital record that proves quality over time.

Cost Reduction

Early defect detection can reduce waste, rework, and recalls. In fact, vision inspection systems have been shown to save up to $200,000 per year per system. Catching issues at the source allows manufacturers to avoid scrapping entire batches of materials, paying for expensive recalls, or risking penalties from regulators.

Efficiency

Vision inspection systems operate continuously and in real time. That means they remove bottlenecks from the production process. Parts no longer need to be pulled aside for lengthy manual checks. As a result, lines keep moving forward without interruption.

Automated inspection also scales easily. Whether you’re producing thousands or millions of parts, it can reduce downtime caused by inconsistent manual inspection. With vision inspection systems, you get a faster, smoother manufacturing flow.

How Hudson Valley Plastics Ensures Quality with Vision Inspection

Hudson Valley Plastics uses advanced vision inspection technologies to ensure our medical partners get the highest quality products. With this technology, we can reduce the risk of defects within the manufacturing process.

Our woman-owned company has decades of experience in the medical space. Our capabilities include everything from design and engineering to custom tooling, decoration and assembly, and more. If you’re looking for a manufacturer that consistently delivers quality products, turn to us.

When you work with us, you know you have a reliable supplier by your side. Ready to learn more about what we can do for you? Reach out to our team for an initial consultation.

No Comments